ONLINE TRANSFORMER OIL LEAKAGE ARRESTING

THE HYPOXY SOLUTION

Leakage of oil from power and distribution transformer is very common problem.

HYPOXY SYSTEMS INC. OF USA offers a time tested unique solution for quick and effective stoppage of such leakages.

INTRODUCTION OF ‘’HYPOXY SYSTEMS, INC,’’ U.S.A

HYPOXY Systems is one of the leading MRO EPOXY SOLOUTIONS provider & a premiere formulator,

manufacturer and worldwide marketer of quality epoxies. The company is headquartered at South

Carolina USA & with the completely automated modern manufacturing facilities, provides

internationally proven Metal & Ceramic filled Polymer compounds for maintenance & repair

solutions.

The HYPOXY Systems Inc. has pioneered the concept of ‘’COLD WELDING REPAIR TECHNOLOGY’’.

Under ‘’CWRT’’ technology, the bonding between metals and ceramics is achieved by cold chemical process and without any heat input as in the case of electric arc or gas welding process.

HYPOXY PRODUCTS -:

HYPOXY range of repair compounds are mostly 2 component systems consisting of the RESIN & HARDNER. The resin contains of finely powdered metals or ceramic suspended in an epoxy filler. The hardner is a chemical curing agent. When the resin and the hardner are mixed in the right proportions, the mixture quickly cures to form the solid mass.

HYPOXY products are engineered to carry out fast insitu repairs and put damaged equipments back into service quickly.

The cured metallic mass will have comparable and often superior physical and chemical properties as compared to base metal.

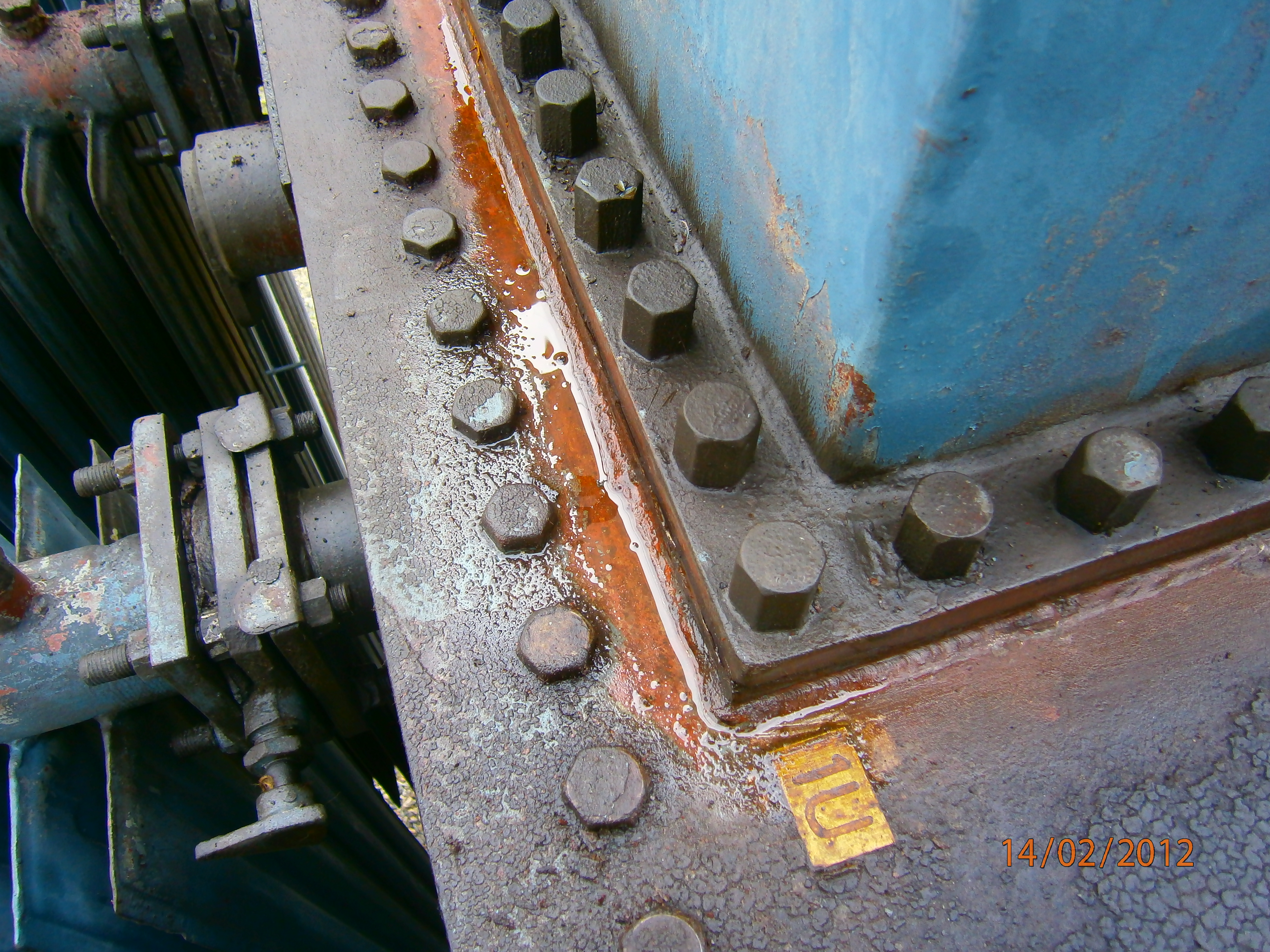

PROBLEM OF OIL LEAKAGE -:

In oil cooled transformer, the oil is used for cooling the transformer windings and in turn to

maintain the system temperature at a particular level. Since there is constant flow / movement of oil

( Due to temperature gradient ), the oil in the transformer is always under pressure.

At all the joining ends like insulators bushings, flanges, radiator cooling fins, parting plates or top

plates etc, the rubber gasket is used to prevent the inside transformer oil to come out which is under

pressure.

Due to various thermal, mechanical & electrical stresses , temperature gradient and continuous

immersion of gasket in the oil and due to aging, the gasket inside the transformer gets hard and

crack at various places.

Due to this, the oil inside the transformer which is under pressure starts leaking out.

Leakage of oil results in -:

- Loss of costly oil.

- Overheating of transformer which results in reduction of transformer efficiency.

- Time and efforts in replenishing oil.

- High cost of repair.

THE HYPOXY SOLUTION -:

Many solutions have been tried out but with limited success and each solution involves draining of transformer oil before any repair can be carried out.

The HYPOXY solution is a quick and easy solution and does not involve drain of transformer oil.

The HYPOXY solution is consisting of two main products

- HyPoxy ‘’STEEL FAST’’

- HyPoxy ‘’TITANIUM BOND’’

- Cleaner / Conditioner for making the surface free from dust, sand and grease etc.

- Reinforcement Tape. – Used additionally if oil leakage is coming out with high pressure.

- Silicon Sealant Tube. – Use to fill in the bolts to arrest leakage from these areas.

The HYPOXY ‘’STEEL FAST’’ is a quick curing product which also has additional property of bonding with oil soaked metal surfaces. It is applied as a first layer and also to immediately arrest the leakage. The HYPOXY ‘’TITANIUM BOND’’ is recommended for 2nd coating and has excellent resistance to water and oil and many chemicals. This layer works as reinforcement layer as well as give extremely high bonding strength.

Aditionally, few more products like below are also recommended.

BRIEF PROCEDURE -:

- Pin point the leakage area and scrape off all the paint from the area.

- Clean and roughen the area using the clean cloth and emery paper.

- Clean and prepare the surface using the Cleaner / Conditioner and hold a cloth pressed to the leak to temporarily stop oozing out of oil.

- Mix small quantity od HYPOXY ‘’STEEL FAST’’

- Remove the cloth and immediately apply the putty over the leak and hold firmly for 2-3 minutes.

- On hardening, inspect area to ascertain leakage stoppage. Apply more if necessary. Use reinforcement tape for additional strength if required.

- Mix and apply HYPOXY ‘’TITANIUM BOND’’ as the case may be over the initial layer and adjoining area on all sides to complete the repair.

TRAINING:- -:The operating staff of a substation can be easily trained to apply these products in case of emergency requirements.

HYPOXY Systems also offers special training courses for group of operating and maintenance personnel from SEB. The company offers application services through nation wide presence of techno commercial executive and managers, Team of skilled applicators along with wide network of authorized dealers located at strategic locations.

We provide complete MRO services like Maintenance survey, assessment of problems, Recommendation of suitable products and services & finally the complete application services. We also provide feedback with the data on financial savings by customers employing our services.

TESTIMONIALS:-The above products and methods are in extensive use in the main and sub stations of various electricity boards and also private power companies.

We can submit few case studies, performance certificates along with job completion reports and job photographs on demand.

SALIENT FEATURES & BENEFITS OF HY-POXY PRODUCTS

- Wide Range – HYPOXY have complete range of Metal filled, Aluminium filled, Titanium filled & Ceramic filled liquids and putties to address wide range of Maintenance needs in the industry.

- Various Pack Sizes. – HYPOXY have small, medium & large pack sizes for all our products, which gives customers the benefits of flexibility in selection of suitable pack sizes as per their requirements.

- Fast curing 5 minutes Aluminium putties in various pack sizes.

- HYPOXY products range has closely linked fillers with high molecular weight polymer binders. This ensures better and higher tensile shear adhesion strength over equivalent products from competition.

- Hypoxy products cures faster & reaches to maximum strength in minimum time ensures reduced down time.

- Hypoxy products have lower water permeability. This ensures better performance when they are exposed or immersed in water.

- When the cured compound is exposed to heat / temp. – dry or wet, the mechanical properties such as Flexural strength, Compressive strength, Tensile shear adhesion strength and Hardness drops at elevated temp. The rate of fall is more steep in competition products than ours. This indicate better suitability / Retainability of mechanical properties at elevated temp in our products.

- HYPOXY range hardener packs are nitrogen sealed for safety, pilferage & long usable life.

- HYPOXY products exhibits long shelf life of approx 5 years if stored well.

- We ensure that HYPOXY products supplied to customers are not more than 5-6 month old from manufacturing date. This ensure customer to enjoy complete 5 years period of ‘’BEST BEFORE USE‘’

We Also offer ready to use ONLINE TRANSFORMER OIL LEAKAGE REPAIR KIT

ONLINE TRANSFORMER OIL LEAKAGE REPAIR KIT- REPAIR KIT-EB''OL-P''

COMPLETE EMERGENCY REPAIR & MAINTENANCE KIT FOR OIL FILLED TRANSFORMERS, REACTORS, CIRCUIT BREAKERS & CAPACITORS

HYPOXY present the perfect solution to emergency situation in your plant / substation.

HYPOXY emergency repair ON LINE TRANSFORMER OIL LEAKAGE REPAIR KIT - EB ''OL - P'' is a

complete maintenance kit for INSITU online leakage arresting of Transformer oil permanently.

This shall allow INSITU repairs without draining out the transformer oil and help to get rid from cumbersome,

messy, expensive & time consuming process of gasket replacement.

The kit is economical , portable , self contained & easy to use for instant & permanent repairs.

RECOMMENDED APPLICATIONS:-

- ONLINE oil leakage arresting from a pipeline

- ONLINE leakage arresting from Radiator fins, Radiator Flange, Bukolz Relay.

- ONLINE oil leakage arresting from Bushing areas.

- ONLINE oil leakage arresting from Transformer Parting plates, Transformer Top Plates.

- ONLINE oil leakage arresting from Ruptured, Wornout & Cracked Gaskets.

- ONLINE oil leakage arresting from welded joints.

- PERMANENT repair of leakages from Pipe, Pumps & Motors etc

- RECLAMATION of bearing & valve seating area

- FACILITATING easy dismantiling of assembly.

| S.NO. | CONTENTS | STOCK | UNIT | QTY | USE |

|---|---|---|---|---|---|

| 1 | FAST CURING ''HY POXY STEEL FAST'' | H 120 | 1 Lb Pack | 6 | Instantly stops oil leakages by bonding firmly on the surface. |

| 2 | REINFORCEMENT COMPOUND ''HY POXY TITANIUM BOND'' | H 900 | 1 Lb Pack | 3 | Final coat for permanent leakage repair. |

| 3 | STEEL REINFORCED ''HY POXY STEEL FAST STICK'' | H 259 | 4 Oz / 114gms Pack | 2 | Instantly stops oil leakages under high pressure as a base coat by bonding firmly on the surface. |

| 4 | SILICON SEALANTS | 310 ml. | 2 | For Insitu gasketing, Repair of Oil Seal gaskets, Electrical Insulation. Stops leakages from Bolt areas. | |

| 5 | CLEANER CONDITIONER | 1 Ltr Pack | 2 | Cleans & Conditions the surface area prior to application of compound. | |

| 6 | CAULKING Gun | Nos | 1 | Application tool for silite tube. |