WELCOME TO HYPOXY SYSTEMS

YOUR QUALITY PRODUCTS SUPPLIER OF THE MOST ADVANCED POLYMER COMPOSITES & PROTECTIVE COMPOUNDS FOR REPAIR OF NON CRITICAL SURFACE DEFECTS IN CAST IRON AND STEEL CASTINGS.

Hypoxy Systems, Inc, USA, one of the leading Epoxy Solutions provider & a premiere formulator, manufacturer and worldwide marketer of quality epoxies provides products & services in north america, south america, europe & middle east markets. The company is headquartered at South Carolina USA & with the completely automated modern manufacturing facilities, provides internationally proven niche solutions in manufacturing / maintenance, repair and overhaul/operations along with customer support on site.

In india, the Hypoxy Systems India Pvt Ltd is promoted by Hypoxy Systems Inc USA to serve and support indian customers & distribution network & have been serving indian industry with our products & services to large nos of Automotive customers.

HYPOXY Steel / Cast Iron castings repair product range is mechanically strong, moderate heat resistant metal repair & filler Compounds which is easy to use and solves many problems faced by metal , steel casting companies and fabricators.

It has a temperature resistance upto 220Centigrade. It is machinable, can be drilled, grinded, filed or, smooth finished with sanding papers and sanding tools. It can give a highly finished metallic appearance to the surface which can be painted , powder coated or, chrome plated. It is highly corrosion resistant. It has a very strong bonding and adhesion to all metals or, non metals.

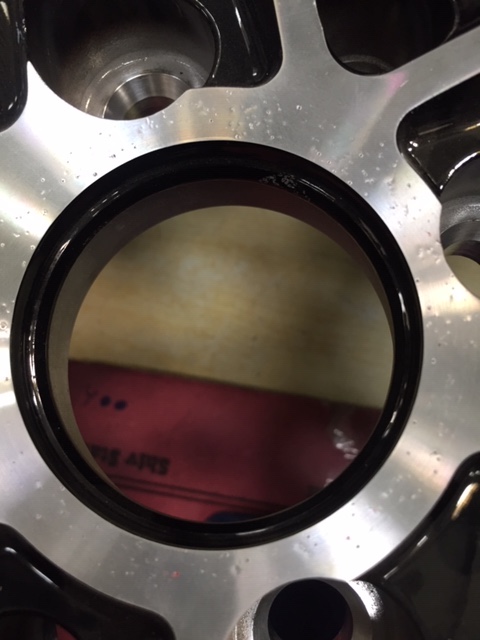

This mechanically strong repair Compounds can be effectively used to repair the blow holes, cracks and other surface imperfections which are visible in castings or, while they do the machining.

Apply Hypoxy Steel / Titanium filled Compounds and patch up the surface instead of breaking and recasting. It with stands high temperature and can be powder coated or, chrome plated.

Easy to use: Hypoxy compounds fills dents and flaws in Cast Iron & Steel Casting easily and economically. Apply with a putty knife or similar tool.

Bonds Permanently: Hypoxy compounds adheres to any clean and dry metal, surface. Its strong bond withstands vibration and other difficult conditions. Hypoxy compounds hardens quickly without heat, providing a durable metal surface. Once hardened, the deposit can be milled, chiseled, drilled, sawed, tapped and machined. Filing, sanding or grinding to a feather edge provides a smooth metallic repair. The Hypoxy deposit will not shrink, crack or peel. Not affected by mild acids, gasoline, oil or petroleum solvents & withstands temperatures as high as 220C (and as low as -40 Degree Centigrade) and when hard, can be painted with lacquer or enamel without danger of bubbling, lifting paint, chipping or peeling. The Hypoxy deposit also stands up to normal paint baking procedures and may also be powder coated.

Efficient, economical: The Hypoxy deposits achieve the metal hardness with greater ease than other materials sold for repair and finishing. Its strength, hardness, durability and abrasion resistance surpass basic standard requirements for fillers set by the metalworking industry. The Hypoxy range of Steel filled repair products are ideal repair putty because of its extensive shelf life, ready-to-use formulation, versatility of applications, strength, chemical resistance and durability.

Curing time: The standard cure products normally cures in approximate 30-45 minutes and fast cure products cure in 5 minute time depending on the thickness of application, and atmospheric conditions. For application guidelines on surface preparation, application and finishing, please refer the product technical details or write to us.

Repair blow holes, cracks and other surface defects in your castings…!!

- Ultimate solution for common problems with metal casters, powder coaters, electroplaters etc.

- Avoid unwanted scrapping of your castings due to minor cosmetic defects.

- Any mechanically strong metal castings can be patched up and repaired to high finish with Hypoxy metal repair Compounds.

- It will give you a very smooth finish metallic appearance.

- Patched / repaired surface withstands high temperature up to 220C.

- It can be powder coated to very fine finish without any problems of bubbles, cracks or, discoloration.

- It withstands powder coating oven temperature and lasts forever.

- Many times metal casters have to encounter situations like imperfect surface finish, blow holes, big or, small cracks, rough surface etc. Here is the solution for you.

IMPORTANT POINTS TO BE FOLLOWED WHILE APPLICATION.:-

- THE COMPONENT TO BE REPAIRED MUST BE CLEAN - FREE FROM OIL, DUST, SAND, MOISTURE.

- SURFACE MUST BE AS ROUGH AS POSSIBLE WHICH ENSURES STRONG BONDING.

- ALWAYS CORRECTLY FOLLOW THE RESIN HARDENER MIXING RATIO.

- WHEN DISPENSING FROM JAR PACKING ALWAYS FOLLOW THE MIXING RATIO ON ''VOLUME'' BASIS ONLY.

- MIX RESIN & HARDENER ON A FLAT STEEL PLATE.

- TWIN TUBE PACK HAS A EQUAL MIXING RATIO SO TAKE OUT EQUAL QTY FROM BOTH THE TUBE.

- MIX VIGROUSLY FOR ATLEAST 3-4 MINUTES TIME UNTIL SINGLE COLOUR MIXTURE IS ACHIEVED.

- FAST CURING TYPE PRODUCTS LIKE H120 & H455 NEEDS TO BE HANDLED FAST AND MIXED FOR ATLEAST 1-2 MINUTES TO ACHIEVE SINGLE COLOUR MIXTURE.

- MIXTURE MATERIAL TO BE APPLIED ON THE CASTING DEFECT AREA BY FINGER, FLAT PLATE OR ANY SUITABLE TOOL.

- WHILE APPLYING, APPLY WITH PRESSURE SO THAT THE MIXTURE MATERIAL CAN GO DEEP AND EVERY mm OF DEFECT AREA IS FILLED WITH HYPOXY MATERIAL.

- LEAVE THE COMPONENT IN THE HORIZONTAL AREA FOR 35-40 MINUTES TIME TO GET THE DEPOSIT HARD. FURTHER OPERATION LIKE GRINDING, MACHINING, DRILLING, TAPING, POWDER COATING, ZINC/CHROME PLATING COATING ETC CAN BE PERFORMED AFTER 7-8 HOURS.

- NORMALLY IF THE REPAIRED SURFACE IS FURTHER PAINTED OR POWDER COATED THEN NO COLOUR MATCHING IS NEEDED BUT IF NO SUCH OPERATION ARE DONE AND COLOUR MATCHING IF NEEDED THEN- WE HAVE FOLLOWING TOOLS FOR COLOUR MATCHING.

A) WHITE COLOUR PIGMENT TO LIGHTEN THE COLOUR SHADE. - THIS CAN BE MISED EITHER IN RESIN OR IN THE RESIN & HARDENER MIXTURE.

B) DARK GREY COLOUR PIGMENT TO DARKEN THE COLOUR SHADE. - THIS CAN BE MISED EITHER IN RESIN OR IN THE RESIN & HARDENER MIXTURE.

C) VARIOUS COLOUR SHADES OF GREY TO MIX IN RESIN HARDENER MIXTURE TO LIGHTEN OR DARKEN THE COLOUR SHADE OF THE MIXTURE.

D) FEW SHADES OF SILVER, GOLD COLOUR MARKER PENS WHICH CAN BE APPLIED ON THE MACHINED / GRIND SURFACE TO ACHIEVE DESIRED COLOUR MATCHING.

E) VARIOUS COLOUR SHADES OF WHITE, GREY, SILVER, CREAM, ZINC SPRAY PAINT AEROSOL WHICH CAN BE EITHER MIXED IN THE RESIN HARDENER MIXTURE. VAROR CAN BE SPRAYED ON THE MACHINED / GRIND SURFACE TO ACHIEVE DESIRED COLOUR MATCHING.

F) EITHER OF ABOVE DESCRIBED OPTION IN ISOLATION OR IN COMBINATION ARE TO BE ADOPTED TO ACHIEVE PERFECT COLOUR MATCHING.